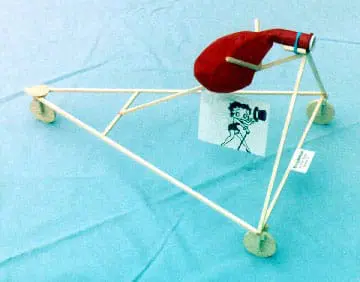

Boopmobile

| Race Order |

Entry # |

Driver Name | Car Name | Mass (grams) |

Length (inches) |

Width (inches) |

Height (inches) |

Distance Traveled (feet) |

Running Time (seconds) |

Awards |

| 5 | 34 | Paul Richter | Boopmobile | 10 | 12 | 9 | 6.75 | 28.75 | 20.19 | Lightest |

Balloon car designer Paul H. Richter, JPL Section 331, writes:

I want to begin by saying that participating in the contest was for me

immensely rewarding. The contest itself was a blast (no pun intended),

and the learning experience involved in the design and construction of

my entry provided many hours of enjoyment – and naturally, not a little frustration.I began by studying some fluid dynamics in order to better understand the

limitations imposed by the balloon itself, considered as a pure rocket.

To this end I dusted off my copy of Sommerfeld’s marvelous treatise,

The Mechanics of Deformable Bodies, one of the most beautifully written

texts on physics ever published, replete with detailed descriptions of

such things as Reynolds’s elegant experiments on laminar and turbulent flow,

for example.It soon became clear that the most efficient use of the elastic energy

stored in the balloon, aside from the obvious one of using it as a rubber

band, was an air motor of some sort, since the exhausting air from the

balloon used as a rocket necessarily carries off most of the energy as

it deflates. However, I could not think of a simple, workable scheme

for building such a motor with the time and resources available, and

hence decided to try to maximize the performance of the pure rocket design.I confess that this decision was to some extent influenced by the Laboratory’s name.

At this point I began to gather data on the characteristics of the balloon

(pressure vs volume diagrams, for example) and the performance of different

nozzle designs, the latter being accomplished through the construction of

a simple but effective test stand consisting of a 1/2 inch x 12 inch thin

walled brass tube suspended from the ceiling by two threads, forming a

simple pendulum. The balloon under test was secured to one end of the

tube, and the nozzle to the other, and the displacement measured as the

balloon deflated, thus permitting a determination of the thrust of the

assembly as a function of time.All of these measurements were made in the kitchen, so that the place

soon took on the appearance of a do-it-yourself physics lab.Using these data, I ran computer simulations at home of runs of a rocket

car under varying assumptions of drag, friction, weight, etc., in order to

determine the optimum design parameters, and finally settled on a light weight,

balsa frame tricycle using a single balloon. The nozzle was fabricated by

forming a 1/2 inch x 1 inch tube of paper around two 1/2 inch by 1 mm thick

balsa discs at either end, with the nozzle itself consisting of a 1 inch length

of small bore glass tubing inserted in holes previously cut in the balsa discs.

Three such nozzle assemblies of different bore were made and tested in the car,

and good agreement was found with the computer simulations.The wheels were fabricated by hand from 1/8 inch thick balsa stock, and used

small diameter brass tubing bearings running on closely matched piano wire axles

for low friction. The front wheel was made steerable by means of a simple vertical

dowel turning under moderate friction in a balsa housing, thus permitting manual

adjustment for optimal steering for a given course. The overall coefficient of

friction for the car, including rolling friction and bearing friction, was found

to be 0.02, which I consider quite good.When tested on the sidewalk in front of my house on the morning of the contest,

the car traveled 55 ft, whereas at the contest it traveled only about 29 ft.

Maybe I was a little nervous, and didn’t blow the balloon up enough, or maybe

there was a slight head wind, or maybe the JPL course is slightly uphill,

or maybe —?As for lessons learned, adding a second balloon would have been relatively

easy, but the thing that intrigues me the most is achieving laminar flow in

the rocket nozzle. My present designs all employ turbulent flow, and there

is a considerable gain in performance to be had by reducing the nozzle

pressure drop through the utilization of laminar flow, and I think I now

know how to achieve this.

MB 1/9/99